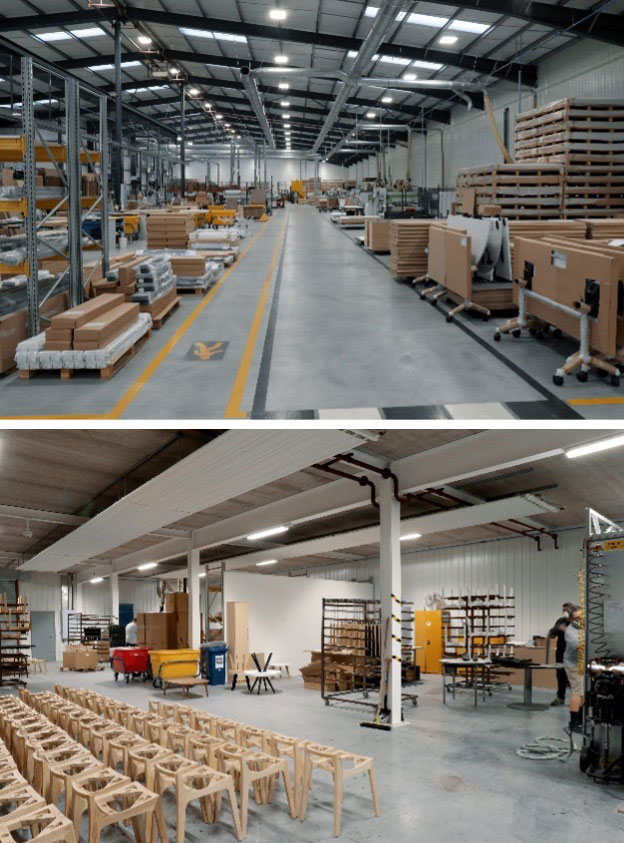

In 2019, Elite Office Furniture opened their new advanced manufacturing facility, head office and showroom in a bid to support further growth in their industry.

Now standing as a multi-million-pound business, occupying 244,254 sq. ft. of manufacturing space and employing 150 people, Elite remain proud of their beginning as a once small family firm powered by local people.

Elite Office Furniture began production in 1986, initially based in Howden. Two years later production moved to larger premises in Goole, with a workforce of just 12 production operatives.

In 2017, the decision was made to invest in a new advanced manufacturing facility as the current premises on Britannia Way had been extended six times during its 30 years of occupation and could no longer support further development.

“We’re delighted to see Goole being acknowledged by world leading enterprises as an area of innovation and investment. Our own investment in the area to responsibly manufacture office furniture and seating is helping to promote Goole’s potential.”

Committed to Goole

During location feasibility studies, it was made clear to the project team that Elite wished to remain committed to the Goole area, primarily to maintain our local workforce and to continue to support the Goole area – ensuring that money is invested back into the local community, boosting the local economy and lowering the area’s unemployment rate. This included using local building contractors during construction with materials sourced from local small businesses.

Their advanced production facility is now fully operational and located adjacent to the M62 motorway. This location was selected for direct access to the heart of the national motorway network, for efficient distribution and to reduce the volume of freight traffic within the town.

Responsible Manufacturing

“Elite’s factory is considered one of, if not the most, sustainable facilities in the furniture manufacturing industry.”

The design of Elite’s new facility incorporates innovative energy saving materials and technology to support their sustainable aims.

This includes the commissioning of a 1MW biomass boiler to heat the factory, coupled with an onsite woodchipper and large silo to store all wood offcuts, supplying feed to the boiler.

LED lighting sourced from a Goole-based electrical contractor was installed throughout the factory, offices and external area, reducing power consumption by around 40%. The lights are controlled by PIR sensors and only activate when movement is detected and the natural lighting level falls below the level demanded by the area’s duties.

More than £8m was invested in advanced machinery that streamlines manufacturing methods, reduces production flows and energy use and substantially increases output to achieve our ambitious goals.

Preserving the Surrounding Ecosystem

Recognising that the surrounding land was an existing habitat for many species of wildlife, Elite wanted to ensure there were responsible steps to mitigate the impact of their development on the surrounding ecosystem. They worked closely with ecology consultants and landscapers to identify a variety of twenty different plant species that would enhance the environment. This included tall-growing evergreen trees placed on the boundary of the site to reduce the visual impact of the building to local residents.

A post-construction ecological survey was carried out and identified newts, bats and rare birds, including three species listed on the RSPB’s Red and Amber Conservation List, had settled in the area. In addition, Elite released 150 common carp and mirror carp to inhabit the pond, where water levels are maintained from falling rainwater on the site and from the surrounding agricultural land, preventing the flood risk of the area.

For further details of our history and continued investment in Goole, please visit: www.elite-furniture.co.uk/our-story.